According to the International Labour Organization (ILO), more than one million work-related deaths happen each year and hundreds of millions of employees suffer from workplace accidents and occupational exposure to hazardous substances in the world.

To mitigate the risk in the workplace, Personal Protective Equipment (PPE) shall be adopted to guard against chemical or toxic hazard exposure. Especially for protective clothing, it can be used in almost every workplace from the food processing commercial kitchen to the industrial factory. During the COVID-19, protective clothing can prevent frontline healthcare operators from contamination if it is worn properly. Therefore, adopting protective garments correctly will be crucial to minimize safety hazards and avoid accidents in the workplace.

How to keep you safe at work?

As knowing the importance of wearing protective garments, other factors may determine whether if the protective clothing is safe enough for the frontline operators to complete their working tasks. Based on ULTITEC’s worldwide experiences of offering body protection solutions over the past decades, follow “The Golden Triangle Rules to Go Home Safely” (Figure 1.) below will reduce the risk of contamination.

Figure 1. The Golden Triangle Rules to Go Home Safely

Figure 1. The Golden Triangle Rules to Go Home Safely

Golden Rule 1. Identify the risk

The risk compliance standards are derived from the hazards present instead of the industry. In addition, not every frontline operator will encounter the same hazards, and a lot of harmful agents are invisible and long-lasting. Hence, before selecting appropriate protective clothing, the first step is implementing the hazard assessment from the staff’s daily operational responsibilities in the workplace.

The common hazardous substances in the workplace

- Gas or vapor: compressed gas, toxic vapor, natural gas, medical gas, chemical vapor, etc.

- Liquid: liquid chemicals, acids, caustic liquids, flammable liquids, etc.

- Particle: dust, mist, fume, virus particles, etc.

These harmful agents may contact the skin through various methods, such as jet, spray, splash, soak, or contact directly. For instance, if there is toxic liquid in the work environment, Type 3 or Type 4 protective clothing is recommended for the operators to protect themselves.

Golden Rule 2. CE Certification

Whilst the types of hazards at the workplace have been identified but cannot be prevented by other methods, protective clothing shall be selected to reduce the hazardous exposure and the danger level. The protective clothing shall be selected must be CE marking under regulation (EU) 2016/425, which is the strictest PPE standard at the present.

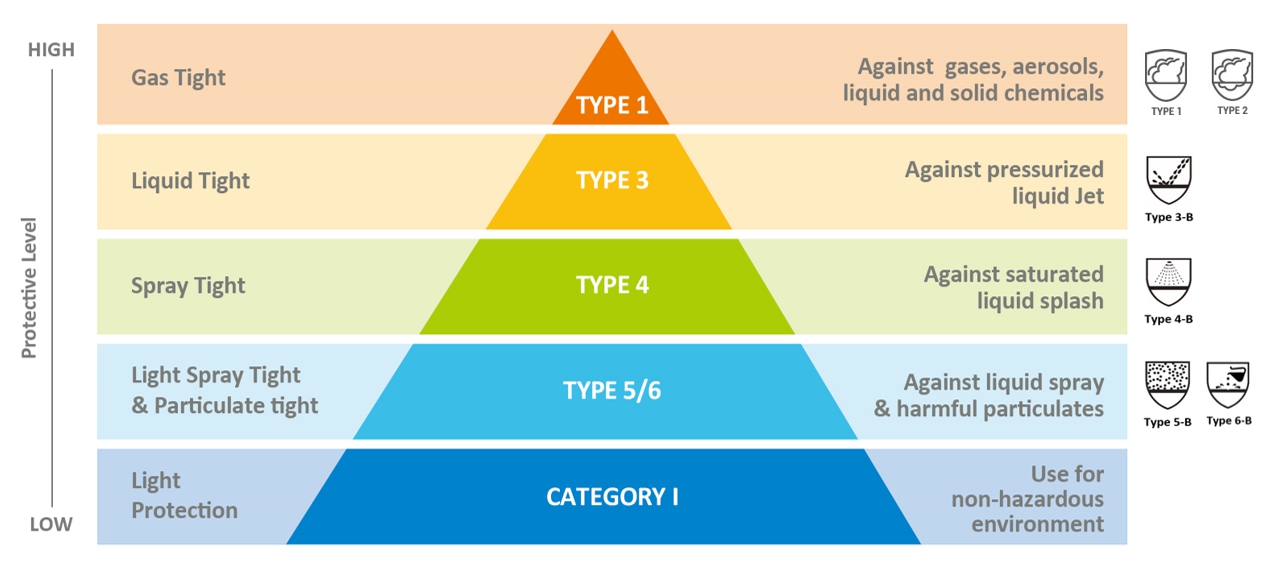

After the confirmation of CE marking protective garment, the first decision that needs to be made is the types of protective clothing, which is following the protective level (Figure 2.) below.

Figure 2. The protective level of protective clothing

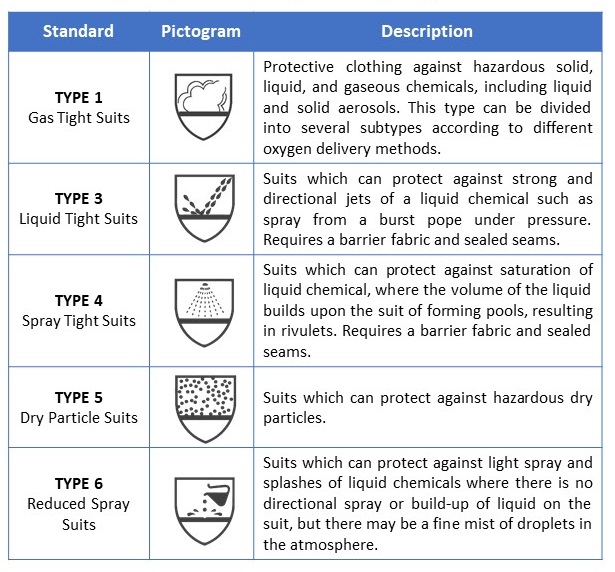

There are a few types of protective clothing that can guard against different hazards.

Table 1. The types of protective clothing

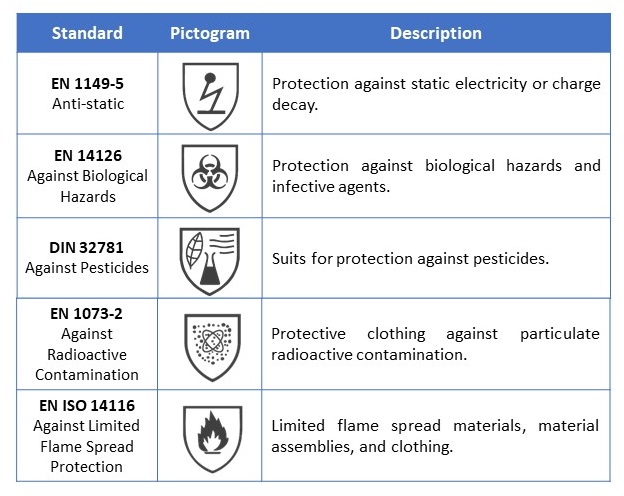

Apart from Type1 to 6, there are other standards of protection for protective clothing.

Table 2. Other standards for protective clothing

Take the hazards of the oil and gas industry, for example, if the operator encounters the risk of high-pressure lines or equipment at the workplace, Type 3 protective clothing will be recommended for keeping safe from the strong and directional chemical fluid jets.

For further information regarding the test methods of the standards above, please click What should you understand about the CE test standard for protective clothing?

Additionally, read the ULTITEC Protective Clothing Selecting chart for knowing the equivalent protective level.

Golden Rule 3. Correct Usage

After the risk assessment and selection of protective clothing with CE marking have been done, would it be safe enough for the frontline personnel in the work environment with potential contaminated risks?

Based on a study published in the Infection Control and Hospital Epidemiology journal, which found that around 40% of healthcare providers did not make PPE doffing process properly, and this resulted in the higher possibility of spreading drug-resistant bacteria and contamination. Hence, the correct application of donning and doffing procedures is a critical factor for minimizing hazardous risks, and this training session shall be provided periodically to ensure the frontline personnel’s occupational safety. ULTITEC has advised the proper donning and doffing instruction as below.

- Donning Processes

- Select appropriate coverall and read User Instruction thoroughly.

- Remove shoes and secure trousers into socks. Step into legs of coverall and place coverall over safety boots.

- Pull coverall towards arms and shoulders.

- Pull zipper halfway up. Put on a face mask (or respirator) and goggles. Pull hood over as head coverings. Cover sleeves over gloves.

- Zip up coverall to chin and ensure hood fits tightly to face, and seal storm flap with adhesive tape if any (Applicable for Type 3 and Type 4)

- Stretch to ensure coverall fits appropriately for ease of work movement and optimum protection.

- Doffing Processes

- Remove adhesive tape (Applicable for Type 3 and Type 4)

- Unzip to the waist.

- Grab outer part and pull hood away from the head. Avoid contaminated gloves to touch the head.

- Release the first arm and strip off the glove from behind the back.

- Release the first arm from coverall and glove. Release second arm and glove from inside of coverall. Sit and roll down contaminated coverall from inside towards outside.

- Draw out legs from safety boots. Use a clean hand to remove goggles and face mask (or respirator) from behind. Fold or roll into a bundle and dispose of coverall responsibly.

Please view the full instruction here or the video ULTITEC donning and doffing instruction.

Disposal and Storage Methods

The correct disposal and storage procedures could also reduce the risk of contamination as well as maintain the efficacy of protective clothing.

- Disposal Method

The contaminated apparel shall be disposed of as the same means as contaminated waste and complied with national regulations; whereas; the uncontaminated apparel shall be recycled and obey with national regulations.

- Storage

The apparel shall be stored in a dry and clean environment within the temperature range from 15°C to 25°C and humidity below 80%. The shelf life is 60 months for ULTITEC products, as time goes by, the user must ensure whether if the antistatic performance is sufficient for the application.

Conclusion

Hazardous risks may cause accidents or deaths at the workplace, and the final line of protection to mitigate the occurrence is equipping with PPE such as protective clothing in the contaminated environment. Keep “The Golden Triangle Rules” in mind and implement these rules in the work environment will help the frontline personnel return home safely. The first golden rule is identifying and assessing the risk at the workplace, then the second golden rule is selecting the protective clothing with CE marking, and the last golden rule is using the protective garments correctly, including a proper donning and doffing process, appropriate disposal methods as well as a suitable storage environment.